Factors Affect Sealing

- Home

- Factors affect sealing

Application Design

Application design has a direct relationship on seal performance. To select the right oil seals for sealing application is necessarily determined by the operating conditions under which the seal must function. Incorrect application design failed in sealing.Medium To Be Sealed

Chemical effects of media being sealing have a determining influence, particularly as operating temperature increase. The sealing compound may either harden or soften depending upon the medium's influence. Hardening results from:Aging phenomena, especially at elevated temperature, caused by media to be sealed. Softening results from :Swelling due to media to be sealed.Temperature

The temperature directly at the sealing edge has a marked influence on the life of a seal , In every case this temperature depends on the heat dissipation conditions at the location where the seal is installed. The excess temperature at sealing edge rises with increasing shaft revolution. Material used for sealing has its operation temperature limit. In choosing the correct sealing material is an important consideration.Shaft Finish

Since the sealing lip contact directly to the shaft, the shaft finish is important for proper seal performance. The shaft finish should be 10-25 micro-inches AA with no machine lead. This shaft finish can be obtained by plunge grinding. Machine lead (helical scores) causes abrasion to sealing lip and possibly act as a pump that give rise to leakage.Shaft Surface Hardness

Sealing life depends on the contact surface hardness of the shaft. Surface hardness should be at least Rockwell "C" 30. There is little indication that hardening above this value will improve the wear resistance of the shaft. When contaminated media or dirt may enter from the outside or when surface speed exceed 15 fps or in situations where the shaft can be damaged (nicked, scratched, etc ) prior to or during assembly, minimum hardness must be Rockwill "C" 45. This will help protect the shaft from possible damage, thus maintaining a flaw-free surface for the seal to run on. Surface hardness should penetrate to a depth of at least 0.3mm. Where shafts can not be sufficiently hardened, a wear sleeve may solve the problem.Shaft Eccentricity

Seal performance can be impaired by two types of eccentricity:1. Shaft to bore misalignment:

Shaft to bore misalignment is the distance that the center of shaft rotation is from the center of the bore. Misalignment cause uneven wear of the sealing lip resulting in a shorter life.

2. Dynamic runout:

Dynamic runout is twice the distance the enter of the shaft displaced from the actual center of rotation. Runout usually is caused by misalignment, shaft imbalance, or actual flexing of the shaft in the application. Shaft runout should be avoid if at all possible or should be kept at minimum limits. Greater runout may cause the sealing lip to lift at high RPM, due to inertia, causing media leakage. The shaft seal must be located next to the bearing and bearing play must be minmized. A spring loaded seal with and adequate flex section will operate satisfactorily if the total eccentricities do not exceed the limits.

Housing Bore And Seal O.D. Tolerances

When installing shaft seals into thin walled housings or housings of relatively low elasticity or strength, the danger of breaking or distorting the housing and seal's case exists. The tolerances of bore and seal O.D. are important to sure an adeqate press fit. Please refer JIS 80401 for recommended bore tolerance.Thermal Expansion of Housing Bore

When light metal, plastic and similar housing warm up, the interference between the housing and the seal O.D. tends to decrease. For seals of Type TB, SB (outer metal case) may lead to leakage at the seal. Shaft seals of Type TC, SC, VC (rubber covered) are more capable of follwing the thermal expansion of a light metal housing because of the elastic rubber covered seal O.D. providing initially tighter press fit and the higher thermal expansion coefficient of the compounds.Housing Bore Finish

A bore finish of at least 100 micro-inches AA (or RMS) without scratches or removal defects, an O.D. leakage problem should not be encountered. If the bore finish is rougher than 100 micro-inches AA (or RMS) a bore sealant-Rubber covered seals should be used to avoid O.D. leakage. On seals without rubber covered, a hand applied sealant should be used, but care should be taken not to get any excess sealant on the sealing element or shaft. Where the lubricant is grease, no bore sealer is required.Pressure

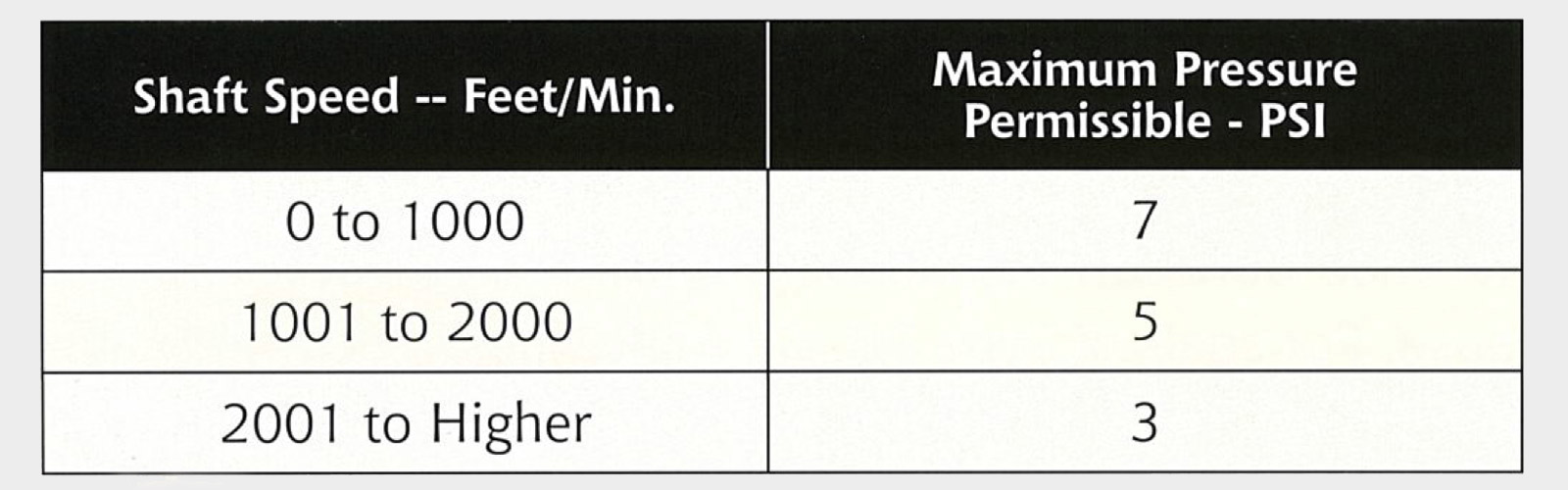

Typical design fluid seals are not intended to withstand pressure. Any internal pressure materially reduce seal life, and means should be provided to relieve internal pressure build-up. Special seal design is required for high pressure sealing. Standard spring loaded oil seals should not be used when the operating pressure in the application exceeds the following limits: